Brushless DC Servo Motor For Industrial Sewing Machines 750W

Our Price:

$169.99

Market Price: $199.99

Save: $30.00 per unit

Sold Out

Universal Sewing Machine Table With Leg Assembly Frame

Our Price:

$249.99

Market Price: $360.00

Save: $110.01 per unit

Sold Out

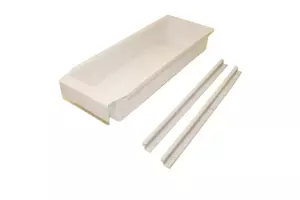

Industrial Sewing Machine Table Top

Our Price:

$199.99

Market Price: $360.00

Save: $160.01 per unit

Sold Out

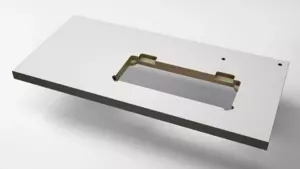

Industrial Sewing Machine Table With Table Frame Assembly

Our Price:

$269.99

Market Price: $360.00

Save: $90.01 per unit

Sold Out

Gooseneck 110 Volt LED Task Light With C-Clamp

Our Price:

$49.99

Market Price: $69.99

Save: $20.00 per unit

Sold Out

Magnetic Flexible Bright 110V LED Light For Sewing Or Hobby

Our Price:

$14.99

Market Price: $19.99

Save: $5.00 per unit

Sold Out

Arm Connecting Timing Belt - Singer #268270

Our Price:

$39.99

Market Price: $69.50

Save: $29.51 per unit

Sold Out

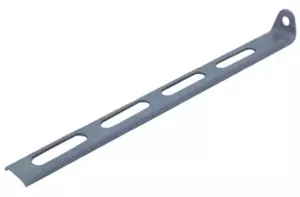

Commercial Sewing Table Hinge Hook #12361

Our Price:

$3.99

Market Price: $4.99

Save: $1.00 per unit

Sold Out

Complete Knee Lifter - Singer #2777H

Our Price:

$24.99

Market Price: $29.99

Save: $5.00 per unit

Sold Out

Synchronizer Needle Position Control For Industrial Sewing Machines

Our Price:

$49.99

Market Price: $85.00

Save: $35.01 per unit

Sold Out

Gray Swivel Sewing Chair - Consew #CH-K12

Our Price:

$199.99

Market Price: $299.99

Save: $100.00 per unit

Sold Out

X-Wide Gray Swivel Sewing Chair - Consew #CH-K28

Our Price:

$199.99

Market Price: $299.99

Save: $100.00 per unit

Sold Out

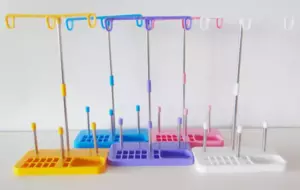

3 Spool Thread Stand for Embroidery, Sewing, and Quilting

Our Price:

$9.99

Market Price: $19.99

Save: $10.00 per unit

Sold Out

5 Spool Sewing Machine Thread Stand

Our Price:

$29.99

Market Price: $59.99

Save: $30.00 per unit

Sold Out

Adjustable Universal Belt Cover- #GS-BG1

Our Price:

$24.99

Market Price: $39.99

Save: $15.00 per unit

Sold Out

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)