Understanding Types of Industrial Sewing Machine Motors and Their Applications

2024-02-27

Sewing machines are an extremely useful tool for sewing enthusiasts, whether you sew as a hobby, work as a professional seamstress, or land somewhere in between. There are a variety of different types of sewing machines designed for various materials, projects, and levels of advancement.

Similarly, multiple styles of sewing machine motors make these machines function at their best. No matter how often you use your sewing machine or what you use it for, it’s important to understand how your machine works so that you can repair or replace parts should you ever need to.

If you’re brand-new to the world of sewing machine motors, don’t worry! Here is what you need to know about the most common sewing machine motor types. You can find out which motor type your sewing machine uses by reading the manual or checking inside your machine.

Brushed/Brushless Servo Motors

The servo motor is the most typical sewing machine motor, which comes in brushed and brushless forms. At its core, both types of servo motors are made up of closed-loop control systems that control the machine’s speed, torque, and position using feedback from the foot pedal.

Brushed servo motors are made with mechanical brushes that interact with the rotor or the motor’s moving part. This connection creates a current of electricity that powers the motor and makes the machine work. Since this process creates energy through friction and heat production, the brushes and other parts of the motor will need to be replaced on a regular basis.

When servo motors are made brushless, they are designed with a set of magnets that attach to the machine’s rotor rather than brushes. These magnets create friction with electromagnetic coils that are built onto the stator or the motor’s stationary part. A magnetic field is created when the magnets and coils interact, which generates power.

Much less heat and friction are caused within brushless servo motors, which means that they tend to last longer. Additionally, the brushless version is able to maintain better torque and speed control, giving the sewer more power over the machine.

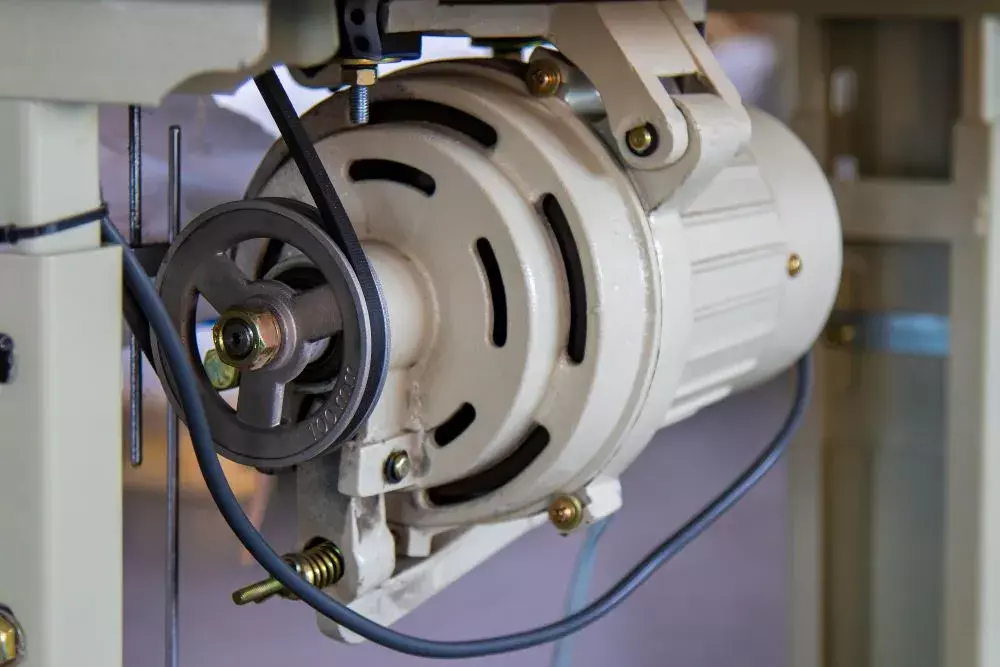

Clutch Motors

Clutch motors use electricity similarly to brushless servo motors. Within the motor is a clutch mechanism that is meant to engage or disengage the drive shaft of the sewing machine from the motor during use.

Clutch motors are easy to use and reliable for many years, but the user’s ability to control output is less precise than with servo motors.

Direct Drive Motors

Some of the most efficient types of sewing machine motors are direct drive motors. This is a version of the brushless servo motor that connects directly to the drive shaft of the sewing machine. This way, no gears or belts are required to power the machine.

Because of this, a lot of the energy lost through the transmission process in other sewing machine motors is saved. Direct drive motors are known to have high torque, so they can create large amounts of power to turn the sewing machine’s needle and make it work quickly.

Sewists enjoy a very consistent and stable experience working with this type of machine, as well as less maintenance and noise.

Why It Matters

Understanding the type of sewing machine motor you’re working with can help you make smarter decisions regarding your projects. For example, some sewing machine motors can’t handle consistent thick fabrics or hours of use each day, while others are created to be able to withstand extremely high workloads.

Once you know what kind of motor your sewing machine uses, maintaining the machine itself becomes easier. You’ll be able to accurately research what type of maintenance your sewing machine needs to last for many years to come. You’ll also know exactly what to look for if you ever need to get your sewing machine motor repaired or replaced.

Find the Right Sewing Machine Motor at GoldStar Tool

Knowing the basics about sewing machine motors, you can set your projects up for success.

Your sewing practice thrives when you have the right tools. Find replacement sewing machine motors, accessories, DIY craft ideas, and more at GoldStar Tool today.