Troubleshooting With a Walking Foot: Common Issues and Solutions

2024-01-23

Sewing multiple layers of fabric is often frustrating, imprecise, and rife with errors. A walking foot is a wonderful solution for sewists who frequently need to sew multiple layers, but it is not without its issues, either.

Be that as it may, if you’re not getting the results you want out of your walking foot, don’t worry! The underlying problem might just be one that has a simple solution.

How Does a Walking Foot Work?

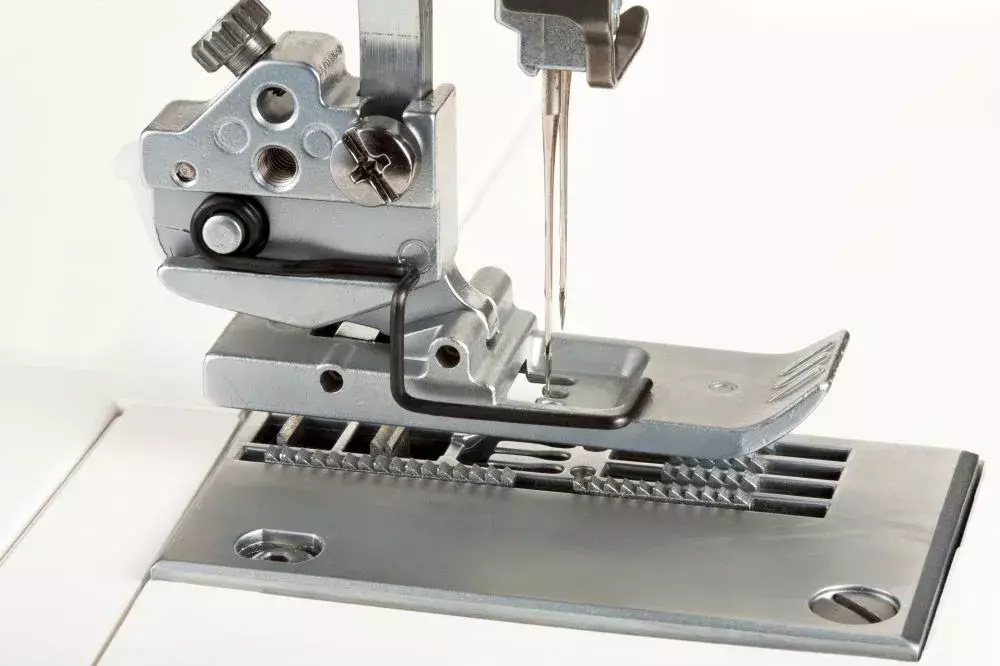

A walking foot is a kind of presser foot that uses ridges called “feed dogs” to move all layers simultaneously. Instead of just moving the fabric by pulling on the top layer, the walking foot grabs the fabric from underneath, as well, which makes it ideal for thick, multi-layered projects such as quilts.

Common Walking Foot Problems

One of the more common issues with the walking foot is a sort of jumping sensation, something you’ll catch on to because the walking foot will genuinely look as if it’s jumping up and down. You might also experience skipped stitches or clicking noises.

Correctly Using Your Walking Foot

Below, you can examine some common fixes for walking foot issues and see if one of them aligns with your experience:

Ensure Your Walking Foot Is Compatible With Your Sewing Machine

The problem you’re facing may simply be due to the fact that you have a walking foot that doesn’t work with your sewing machine. The easiest way to figure out if your machine can accept the walking foot you’re trying to install in it is to check the user manual. If you don’t have it, you can always contact the manufacturer and ask them directly.

Still, if you can’t get the answer you’re looking for, you can figure things out with some simple measurements. Measure your machine’s shank and compare it with the walking foot’s shank requirements. You may find that you have a low shank machine (¾”), but your walking foot needs a slant shank machine (⅛”).

Install Your Walking Foot Properly

Depending on the type of walking foot you have, it may install on the snap-in assembly, or it might require installation on the screw. A walking foot with a bar will install on the top of the screw holding the needle, but if the walking foot uses a forked piece, it will go around to the right of the needle screw. If it’s properly installed, it will be flush with the needle plate, and you should not experience any more jumping, clicking, or skipped stitches.

Only Stitch Straight Lines*

A walking foot is meant for straight stitching, so if you’re trying to stitch in different directions, such as a zig-zag or sideways pattern, it will not work. On top of that, never stitch backward with the walking foot in place, as it physically pulls the fabric through in one direction. Trying to force the fabric in the opposite direction won’t yield good results.

*There are walking feet that will stitch in zig-zag patterns, but they are specially designed to do so. Unless you have one of these, do not attempt to make the patterns.

Don’t Go Too Fast

Even though a walking foot provides more grip on the fabric, you’ll still discover errors if you sew too quickly. With that said, you’ll want to sew at a medium speed at the fastest unless your walking foot and compatible sewing machine are designed for higher speeds.

Maintain Your Walking Foot

Inspect your walking foot regularly, looking out for signs of wear, damage, or any obstructions. Your walking foot will also need cleaning on a consistent schedule.

Adjust Your Walking Foot

Even if you have followed each of the tips above, your walking foot may still give you problems if you don’t adjust it, which is especially important if, after you’ve made sure you installed it correctly, it is still jumping and clicking. Adjusting your walking foot will ensure it uses the right pressure to feed fabric without slipping or grabbing with too much force.

Get Quality Walking Feet at GoldStar Tool

From a new walking foot to all the parts and materials you need to maintain your current one, turn to GoldStar Tool. We have walking feet for both in-home and industrial machines, whether you want to stitch cording, zippers, fabric, or other materials, so start browsing our vast selection of walking feet today!