The Complete Guide To Sewing Machine Needles and Sizes

2022-12-22

The needle isn’t a new invention. A sewing needle found in 2016 in the Denisova Cave dates back about 50,000 years, showing that humans have been using needles for millennia.

During the Bronze Age, about 10,000 years ago, humans started making crude needles from copper. Later, they used other metals, like bronze and iron. Oxidation has destroyed most of these old metal needles, but there is evidence from early embroidery artifacts that these needles were sophisticated.

For thousands of years, the needle remained the same basic design, with a point at one end and an eye at the other. In 1755, when Charles Fredrick Wiesenthal, a German physician, invented a device with a two-pointed needle, sewing needles started to change in a revolutionary way.

In 1810, Balthasar Krems created the sewing machine needle that paved the way for modern sewing machines. Krems put the eye of the needle at the same end as the point, and all modern sewing machines use this concept to sew everything from car seat covers to clothing items.

How to Choose the Right Sewing Machine Needle

.webp)

Today, sewers have the luxury of choosing from hundreds of sewing machines and needles to find the right equipment for their projects.

With all of these options, knowing how to choose the right sewing machine needles can be overwhelming. The wrong sewing needle can damage your fabric, break your thread, and cause poor stitch quality.

Difference Between Industrial and Domestic Sewing Machines

There are more similarities between industrial and domestic sewing machines than differences. They can both be used for various quilting and crafting projects with all different types of material.

Industrial machines are made for businesses and manufacturers. They are faster, create a higher quality stitch, and can sew heavier fabrics with heavy-duty threads. Commercial machines are built to last, and some commercial embroidery machines, like the Meistergram GEM series, are just starting to break in after a million stitches.

On the other hand, domestic machines are slower, which is suitable for beginning sewers. They don’t need to be cleaned like industrial machines and often have several programmable stitches. Domestic sewing machines don’t have as high quality a stitch as commercial machines, but they are excellent for home use.

Sewing Needles for Commercial Use - How To Choose The Right Machine Needle Sizes

Industrial sewing needles are curved or straight and designed for different sewing styles. Straight needles sew a traditional chain stitch or lockstitch, and curved needles are used for blind stitches, which create invisible hems for products like pants, skirts, and curtains.

To choose the right sewing needle for your industrial sewing machine, you need to identify your needle system, decide which needle point to use, and determine the best size needle for your project. Needles for commercial use come in different sizes for different material thicknesses. Think of your sewing needles as tools for a home project.

Sewing Needles for Home Use Including Fabric, Thread and Other Materials

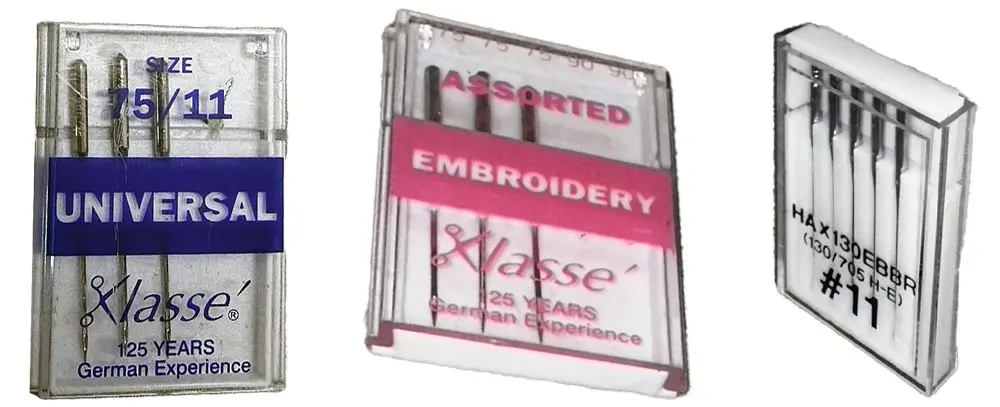

Most home sewing machines use a needle system called 130/705H, which is different from industrial machines. Commercial and home machine sewing needles are not interchangeable.

Since home sewing needles are standardized, you won’t need to worry about the brand. Instead, you only need to focus on the needle type and size.

It’s essential to change your needles regularly. You should change them after about 8-10 hours of sewing, regardless of the types of fabric or when you hit a pin. If they are bent or dull, they can damage your fabric and your machine.

Sewing Machine Needle Types

Sewing machine needles for home use come in different types and sizes. However, since there are many types of fabric, there are also many types of needles.

Ballpoint Needles

Ballpoint needles have rounded tips, as the name suggests, and are used for knit fabrics. Instead of the needle piercing through the fabric, a ballpoint needle easily slides between the weave of lightweight knit fabrics, creating a stitch that is less likely to break when the knit is stretched.

Using a regular universal needle on knit fabrics will cause the fabric to curl. It will also damage the fabric by pulling the strings and causing them to snag. Using a ballpoint needle will prevent skipped stitches.

Universal Needles

Universal needles are used on all woven fabrics, including linens and denim. These are the most common needles used in most home sewing.

Universal needles have a sharp point that is slightly rounded. It can slip through fabrics easily, like a ballpoint needle, but it can also pierce through multiple layers of fabric.

Sharp Needles

Sharp needles have sharp points and can pierce through fabrics. They are excellent for precision stitching techniques. The Schmetz brand of sharp needles is called Microtex.

Quilting Needles

Quilting needles are sharp needles with strong shafts built for going through several layers of fabric.

Stretch Needles

Sewing with stretchy fabrics like Lycra or Spandex is much different from sewing woven fabrics like cotton. A special stretch needle with a slightly rounded tip helps make the job easier.

Denim Needles

Denim is a tightly woven fabric made from thick fibers. You need more than a standard universal needle to sew denim, canvas, or cotton duck. Denim needles have a strong shaft and a sharp point.

Twin Needles

Twin needles are used when you want two parallel rows of stitching, which is common in decorative stitching. There are also triple sewing needles available for sewing three rows of stitching.

Leather Needles

Leather needles have a strong shaft and a sharp point for piercing through leather.

Sewing Needs By Project

To choose the right sewing needle for your home sewing project, you must first decide what type of needle you need. It’s a good idea to check your sewing machine manual for recommended needle sizes and brands.

Sewing needle sizes have two size numbers, European and American. The smaller the number, the smaller the needle size. The number is the size of the needle shaft.

- European sizes 60 to 120

- American sizes 8 to 19

Change your thread size with your machine needle size to avoid breakage. You may also need to change the presser foot or tension if you still have problems.

Start your project with a new needle if your fabric requires a sharp needle. Don’t forget to replace your needle after about 8 hours of use. Heavy textiles will dull a needle faster, and you might have to change them after about 6 hours.

There are many types of fabric, which range in weight from very lightweight to very heavyweight. Use this chart to help you decide which size sewing needle is right for your project. The important thing to know is that the lighter the fabric, the smaller needle you will need.

Fabric Weight | Examples | Needle | Project Types |

Lightweight | Sheer fabrics, crepe, silk, chiffon, organza, rayon, gauze, tulle, net, lace | 60/8 to 75//11 Universal | Light blouses, flowy dresses and skirts |

Lightweight knits | Sheer knits, tricot, Spandex, Polyester, jersey knits | 10/70 to 12/18 Ballpoint | Light knit shirts, baby clothes, athletic wear |

Medium Weight | Cotton weave fabrics, satin, taffeta, jersey, velvet, oxford, sateen, poplin, rayon, broadcloth, knit, elastic, linen, light denim, light flannel | 75/11 to 90/14 | Dresses, shirts, blouses, lightweight jackets |

Medium to Heavyweight Knits | Sweatshirt, double knits, sweater knits, wool knits | 14/90 Ballpoint | Hoodies, sweaters |

Heavyweight | Denim, canvas, corduroy, cotton duck, suede, tweed, wool, flannel, light leather, oilcloth, velour, stretch denim | 100/16 | Pants, bags, jackets, fall jackets |

Extra Heavyweight | Upholstery, leather, heavy denim | 110/18 | Coats, upholstery, heavyweight pants |

Do Brands Matter When Choosing a Sewing Machine Needle?

Since sewing machine needles are standardized, you can use any brand with your machine. Several popular sewing machine brands also manufacture needles. That means you can use any brand, whether you use a Juki, Brother, Pegasus, Singer, Conosew, or New-Tech sewing machine.

Sewing Machine Needle Brands

There are several popular brands of sewing needles, such as Schmetz, Singer, Groz-Beckert, and Dritz. All of these brands make interchangeable needles for home sewing machines.

Many of these brands also manufacture other sewing machine accessories.

Schmetz

Schmetz needles have been manufactured since 1851 when sewing machines were first invented. Schmetz started production in Germany and became an international sewing needle manufacturer in 1965. They relaunched their brand in 1997 to develop as a leading global supplier of high-quality needles.

Singer

1851 was a big year for sewing, as this is also the year that Isaac Singer started the Singer Corporation in New York. Singer sewing machines gained popularity early because of their “unbreakable” needle. Over the years, the Singer Corporation has marketed its machines and components to homemakers and made the sewing machine a household appliance.

Groz-Beckert

Following on the heels of Schmetz and Singer, Groz-Beckert started manufacturing sewing needles in Germany in 1852. Within ten years, Theodore Groz was producing 10,000 needles each week. Today, they are a top provider of industrial machine needles and other components.

Dritz

Dritz is another well-known sewing brand that has made all types of sewing notions since the early 1900s. The Drtiz company was bought by the Prym USA company, which owns brands like well-known thread maker Gutermann and yarn manufacturer Lana Grossa.

Organ Needle Co.

The Organ Needle Co. started in the 1920s in Tokyo, Japan as a manufacturer of needles for gramophones. They are committed to staying flexible with changing times and technological innovations. They have been producing sewing needles since 1938.

Janome

Janome is another company with its origins in Japan. The word Janome is Japanese and means “eye of the snake.” The original brand, Clark & Barker, was developed in 1860, and Janome purchased the company in 1960.

Juki

Another Japanese company that produces excellent sewing machines and needles is Juki. For over 75 years, Juki has been supplying its products in over 170 countries worldwide.

There are many high-quality brands of sewing machines and needles, and you have several excellent options to choose from when deciding which needles to get.

The Composition of a Sewing Machine Needle

To create the perfect needle for various fabrics and projects, manufacturers must make slight adjustments to the different needle parts.

Butt

The beveled end opposite the point is called the butt.

Shank

The shank is the part that is inserted into the machine. It is flat on one side so that you can insert it easily.

Shoulder

The shoulder is the slope between the shank and the shaft.

Shaft

The different sizes refer to the diameter of the shaft, which is the needle’s body.

Front Groove

Above the eye of the needle, there is a slit which is called the front groove. It helps to create smooth stitches by reducing friction by guiding the thread toward the eye.

Point Scarf

The scarf length varies with different types of needles. It is the indentation just above the eye. As the needle carries the thread through the fabric, the scarf lets the bobbin hook get close to make the stitch loop.

Eye

The hole at the end of the needle is called the eye, which is used to hold the thread. The size of the eye varies with different needle types and sizes.

Point

There are different shapes of points for various needle types, such as ballpoint and universal needles.

Tip

The tip of the needle varies in sharpness. Ballpoint needles aren’t sharp at all, but Microtex needles are very sharp for piercing through the fabric.

Singer’s Color-Coded System

All sewing needles have their size engraved on the top of the shank. Singer needles have colors that make it easy to identify the size and type of needle at a glance.

Each needle has two colors which represent the needle's style and size. The top color is the style color.

Color | Fabric | Style Number and Type |

Red | Woven | 2020- Universal |

Yellow | Knits | 2045- Ballpoint |

Blue | Denim or jeans | 2026- Denim |

Brown | Leather or vinyl | 2032- Leather |

Dark Gray | Embroidery | 2000/2001 Chromium embroidery needles |

Light Gray | Knits | 2022/2054- Overlock |

Purple | Quilting | 2019- Quilting |

The color on the shoulder of the needle is used to designate the needle size.

Color | Size | Fabrics |

Green | 70 | Very lightweight |

Orange | 80 | Lightweight |

Blue | 90 | Medium weight |

Violet | 100 | Heavyweight |

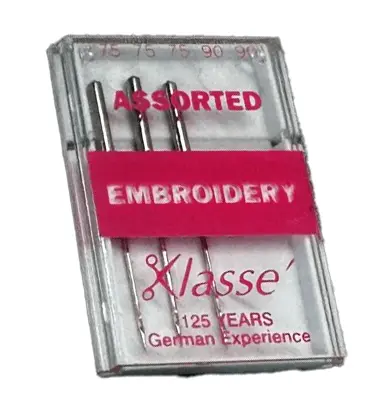

Embroidery Needle vs. Sewing Machine Needle

Many home sewing machines have advanced embroidery features. If you want your machine embroidery to be high quality, you must choose the correct needles for the job.

Embroidery thread is fine, and sewing machine embroidery needles have a different size scarf than regular needles. They also have a larger eye that helps prevent fraying, which causes the thread to break.

Machine embroidery uses many more stitches than regular sewing, so needles made of chromium are recommended because they will hold up to the heat caused by the high stitching speed of embroidery. Embroidery needles are more expensive than regular needles because of this.

Use universal point chromium needles on woven fabrics (Singer style 2000) and ballpoint chromium needles on knit fabrics (Style 2001).