How to Maintain and Extend the Lifespan of Your Fabric-Cutting Machine

2023-11-07

While the sewing machine is the core tool used in sewing and DIY projects, many other useful tools can make manufacturing much easier. Whether you work in commercial garment production or are a passionate at-home sewing enthusiast with various projects, supplementary tools like fabric-cutting machines can make your job much faster and easier.

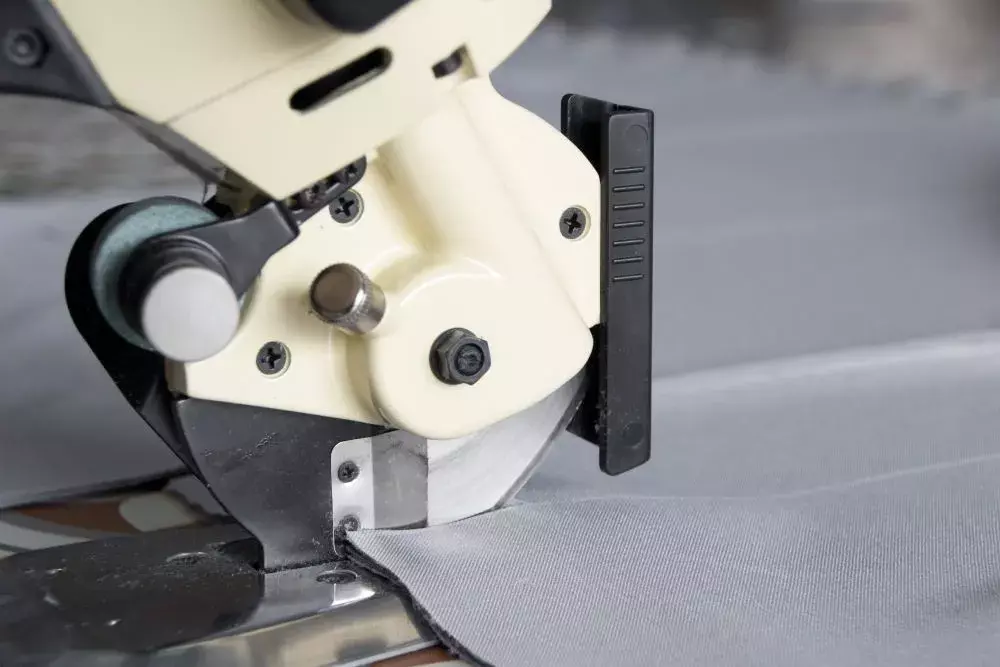

The fabric-cutting machine is designed to cut through fabric cleanly so you aren’t left with stringy ends or uneven cuts. While these machines are especially crucial for professional sewists managing quality control, they also make it possible for DIY crafters to make professional-quality items they can enjoy for years.

Why Is Fabric-Cutting Machine Maintenance Important?

Like any machinery, it’s important to maintain your fabric-cutting machine regularly. If fabric-cutting machines are used consistently without maintenance or picked up again after a long period of disuse, the machine could lose its function.

Additionally, a poorly maintained fabric-cutting machine could even put the user at risk of injury. The cutting mechanisms in these machines are extremely sharp, so they can cut through even the thickest fabrics. You shouldn’t risk using one that hasn’t been properly maintained.

When to Schedule Maintenance

If you’re new to sewing, you may not know when to perform maintenance on your fabric-cutting machine. The type of machine you have and how often you use it will both play significant roles in this decision, so you should start by referring to your user manual to see how often maintenance is recommended for your model.

Once you understand your machine’s maintenance needs, it’s best to schedule it based on the hours used or a specified time frame. If you use your machine very frequently, you should check its oil, gear movement, cutting sharpness, and other markers of proper maintenance based on the number of hours you’ve used it since the last time.

Conversely, if you do not use the machine very often, you can schedule your maintenance on a set time frame, such as once every three months. Your machine’s manual should have a recommendation about this timeframe.

Types of Maintenance for Fabric-Cutting Machines

Did you know that there are multiple types of maintenance that you can perform on a fabric-cutting machine? The maintenance style you’re performing will affect the specific actions you take.

Predictive

If your machine is connected to predictive software, the software can detect potential future malfunctions and recommend maintenance tasks to prevent them. When you take this action, it’s known as predictive maintenance.

Preventive

Preventive maintenance consists of the steps to ensure your fabric-cutting machine continues to work consistently.

For example, if you’ve decided to maintain your machine every three months, you’ll carry out preventive maintenance steps like changing the oil and cleaning the interior every three months, even if no issues have arisen. This helps to prevent any problems or malfunctions from occurring.

Corrective

If your fabric-cutting machine breaks down or makes a mistake and you must fix it, this is known as corrective maintenance. Once you perform these fixes, it’s important to test the machine to ensure it’s back in working order before continuing your project.

Productive

Performing productive maintenance means changing certain aspects of your fabric-cutting machine based on developments in the industry. An example would be installing newly released software on your machine to continue maximum productivity even if the old software isn’t malfunctioning.

Detective

What if your machine isn’t broken, but you can tell certain aspects aren’t performing like they should? This is known as detective maintenance, or repairing a minor issue to avoid developing into a much larger problem later.

The smaller the issue, the easier it is to fix, which is why detective maintenance is preferable to corrective maintenance. Nipping maintenance issues in the bud will save you significant money and hassle in the long run.

High-Quality Fabric-Cutting Machine Parts and More at Gold Star Tool

A great fabric-cutting machine can make your sewing experience so much more enjoyable. Take a look at our site and find replacement parts (or even your next new machine) at Gold Star Tool.