How Often Should You Change Your Sewing Machine Needle?

2024-10-09

Does your passion lie in assembling an intricate log cabin or mariner’s compass pattern? Alternatively, perhaps you enjoy making clothing and accessories for yourself and loved ones, or you’ve turned your talent for needlecraft into a business.

Whether you sew for fun or for your livelihood, you need to make sure the tools of your trade are well-maintained. This means cleaning and oiling your sewing machine regularly and keeping your shears and rotary blades sharp.

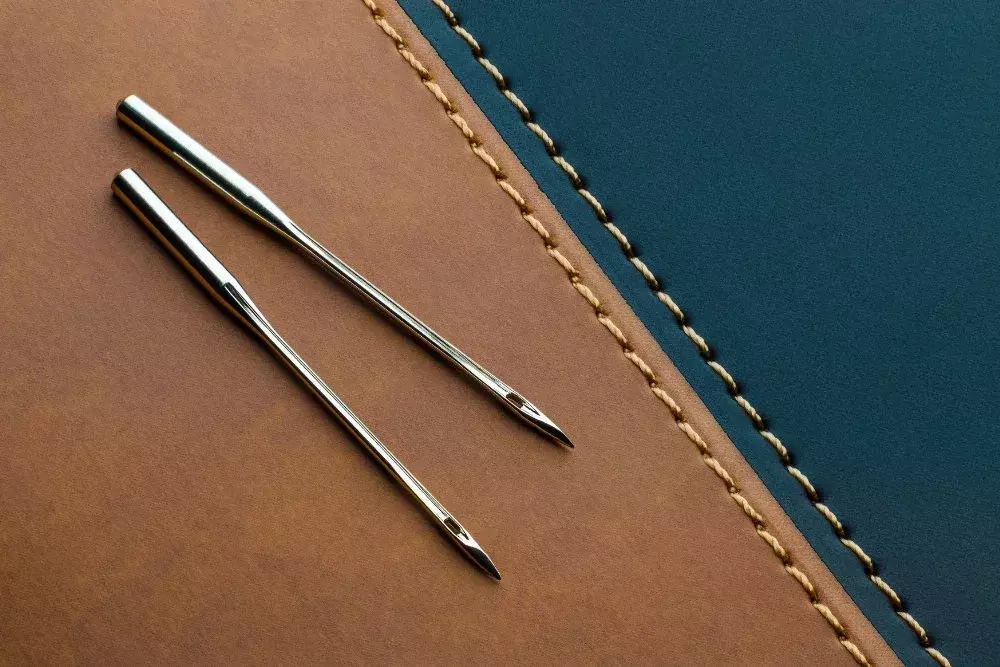

But what about your sewing machine needles? How often do they need to be swapped out to ensure that your stitches come out perfect, without a wrinkle or broken thread? Here are a few things you should know about changing your sewing machine needles.

Is There a Time Frame for Maintenance?

Many factors could contribute to wear and tear on your sewing machine needles, including how often you use them and what you use them for. Are you sewing lightweight linen or heavy denim, for example? Will you spend several hours sewing a quilt or just a few minutes hemming a pair of pants?

When you use the right size of needle for the job and the fabric, you should get at least six to eight hours of continuous use. You can probably expect a couple more hours if you use your machine infrequently and for short projects.

However, the average person may not time their machine use or could forget to keep track of several short uses. A better gauge of when to change sewing machine needles is performance.

Issues to Watch For

A sharp needle that’s suitable for the type and weight of fabric you’re sewing will punch through with no problem, creating a straight, seamless line of stitches. When you start to see issues affecting the thread or fabric, it may be time to swap in a fresh needle.

Thread Problems

One of the first indicators that your needle is done in is breaking thread. The tip of your needle dulls as it passes through the fabric at a rate of about 600 to 1,000 stitches per minute.

What you may not realize is that the thread passing through the eye of the needle can also cause wear, creating a groove that results in frayed, torn, or broken threads. If you find yourself frequently rethreading due to snapped threads, it’s probably time for a new needle.

Skipped or uneven stitches could also be a sign of a worn needle. If your tension setting is correct, check to see if your needle has been dulled or nicked.

Fabric Problems

Some fabrics are more likely to pucker along seams or show damage just because they’re more delicate or tightly woven. However, these issues could also be signs that you need to replace your needle.

Keep Needed Needles on Hand

If you sew often, it’s best to have a range of sewing machine needles on hand. Not only does this allow you to account for different projects with a range of fabrics, but it also ensures that you always have the replacements you need on hand.

GoldStar Tool has everything you need to complete home projects or start your sewing empire. Contact us today to find the best tools for your needs.